What is Stormwater Management?

Whenever there is land development, e.g. houses, roads, parking spaces, commercial buildings, hotels, supermarkets, etc., on which it rains heavily, there will be a quantity of stormwater than needs managing, which previously would have been absorbed into the ground.

To begin with, this is a problem because the water does not infiltrate into the soil so the water table is lowered. Secondly, if the water has nowhere to drain to (or drain to fast enough), it will flood the surface, potentially causing water damage to the property or surrounding land. Thirdly, if a mains drainage network exists which this stormwater can be connected to, there is a possibility for that to become overwhelmed with the additional stormwater and flood either the property/land in the immediate vicinity, or a property downstream. Finally, climate change will aggravate the problem by increasing the quantity of water discharged during a storm, thereby making the problem worse for future land development.

For this reason, there has been a marked increase in demand for stormwater management systems on all developments in recent years.

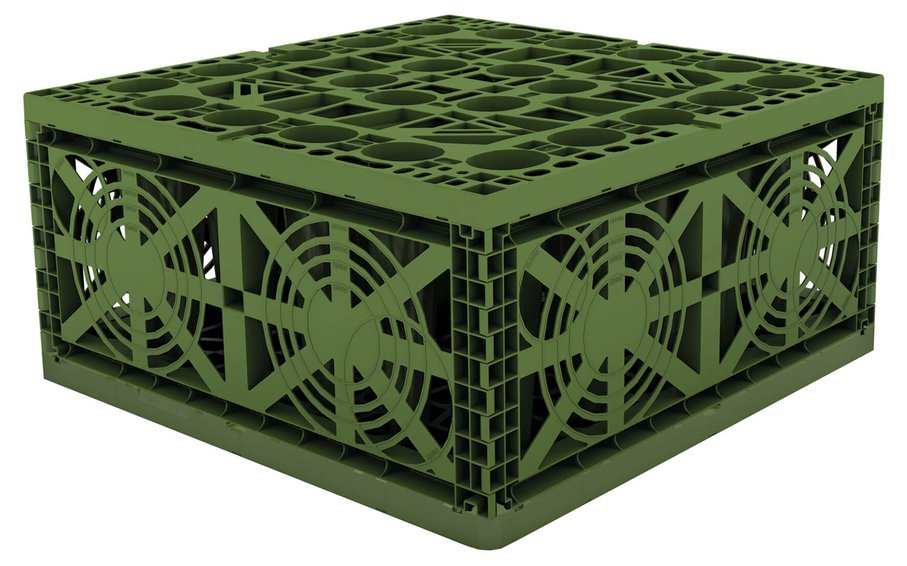

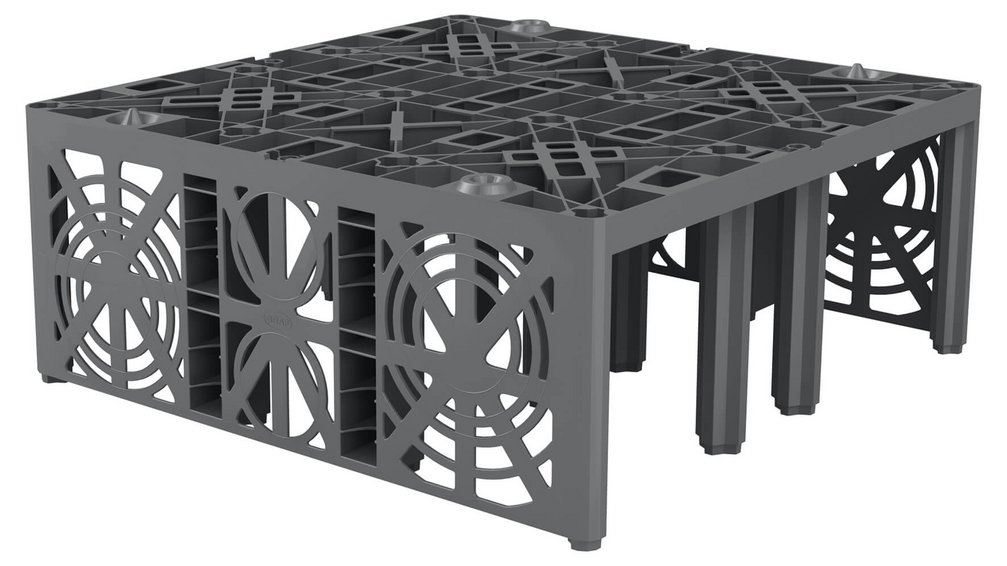

As one of several solutions for stormwater management tanks, crates/geocellular systems are a popular choice for surface water management. Our EcoBloc range is therefore ideally suited for this growing requirement.

What can we do?

Design assistance:

Send us your drainage layout drawings and we’ll do the rest…

We’re often making changes to the tank design to make it as cost-effective as possible. We’re adding value by making sure our proposal not only meets the needs of the job but also adds some sort of benefit. Whether it is a slight change in the tank depth to reduce the footprint for reduced dig, or adding inspection channels and access shafts to enable future inspection and maintenance of the tank, we’re always looking for ways to offer additional value to our customer, and our customer’s customer.

The best wins come when we’re involved early in the project. When it’s at the design stage and we’re consulted to input on the original design. We’ve saved our customer’s clients’ money by checking tank size requirements to actually reduce the amount of storage that is required by carrying out our StormFlow calculations which determine what tank size is required to meet the standards and discharge rates from the tank. We’ve also worked on projects where the tank has been moved to a much higher level within the ground, removing the requirement to excavate down to below 5m underground, with all the risks and costs involved with working at such a depth, and we’ve saved our customer both time and money in the process by a simple change in the location and position of the tank.

Value-engineering is all about looking at the bigger picture. By not just offering a like-for-like product we look at the overall scheme, the overall drainage layout, and we work out a way to offer some additional value. For further information on our design & drawing services, please click here.

Supply & installation package:

It seems to have become the norm for many contractors to want to place orders for stormwater attenuation tanks on a supply and install basis. You can see why when you fully understand what is involved with the installation of crates. No, it’s not the stacking of the blocs or the clipping them together, of course really anyone can do that bit. It’s the welding of the geomembrane. The most important part of the whole tank when you think about it.

All the crates are doing is creating a large void underground. It’s the fact that they’re wrapped and sealed in a completely watertight liner that they actually perform a job. Of course, they have to be structurally sound and capable of withstanding whatever loading may be placed above them on the finished surface level, but the truth is that the crates are just a means to an end. The truth is that without being used in combination with the 1mm thick LLDPE geomembrane liner, they’re no use to anyone! (unless you’re creating a soakaway/infiltration tank that is) It’s the water-tightness of the membrane, especially the welded seams of the membrane, that are crucial to the actual performance of the tank. That’s why orders get placed on a supply and install basis.

The added benefit when you place orders with a specialist on a supply & fit basis, is that you know it will be done in the quickest and most effective way possible, with a guarantee that the sealed membrane is watertight. For further information on our installation package, please click here.